Europas Technologieführer für innovative Formteile und komplexe Gehäusesysteme aus Partikelschäumen

Wir sind Ihr Lösungspartner für Komponenten, Baugruppen und Systeme – basierend auf Partikelschäumen. Mit unseren Entwicklungs- und Montagedienstleistungen schaffen wir individuelle Lösungen für Sie.

RUCH NOVAPLAST: Unsere Formteile verbessern Ihre Produkte hinsichtlich Funktion, Qualität und Wirtschaftlichkeit

Als Spezialist für Partikelschaumlösungen entwickeln wir innovative Formteile und komplexe Gehäusesysteme aus nachhaltigen Werkstoffen. Dank unserer eigenen Fertigungstechniken gewährleisten wir Ihnen höchste Funktion, Qualität und Wirtschaftlichkeit. Mit unserer Expertise schaffen wir individuelle Lösungen für anspruchsvolle Branchen – stets mit dem Ziel, Ihre Produkte zu verbessern.

Spannende Einblicke in unsere Arbeit, unsere Werte und unser Team

Sie möchten mehr darüber wissen, wie wir als Anwendungsspezialist von thermoplastischen Granulaten arbeiten? Dann lernen Sie die Menschen hinter RUCH NOVAPLAST kennen und entdecken Sie, wie wir ideen form geben.

Innovative Werkstoffe für die Zukunft im Fokus

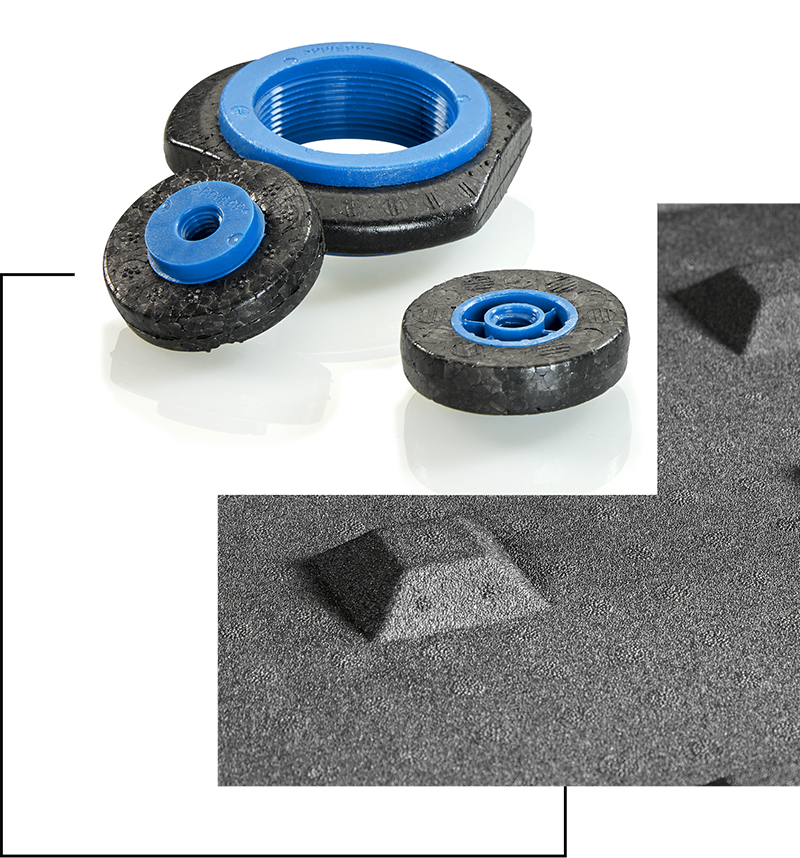

Unsere Expertise liegt in der Verarbeitung innovativer Partikelschäume mit hervorragenden thermoplastischen Eigenschaften und großem Leichtbaupotenzial. Wir setzen auf leistungsstarke, nachhaltige Werkstoffe, die vielfältige Anwendungsmöglichkeiten bieten.

EPP

Expandiertes Polypropylen bietet Flexibilität, hohe Druckfestigkeit und hervorragende Wärmeisolierung. Ein vielseitiger Werkstoff für langlebige, funktionale Lösungen.

EPS

Expandiertes Polystyrol überzeugt durch hervorragende Energieabsorption und Wärmeisolierung bei gleichzeitig geringem Gewicht. Die optimale Lösung für anspruchsvolle Anwendungen.

ETPU

Expandiertes thermoplastisches Polyurethan bietet hohe Flexibilität, Elastizität und 100 % Energiespeicherung. Die perfekte Wahl für flexible und strapazierfähige Lösungen.

EPA

Expandiertes Polyamid überzeugt mit hoher Temperaturbeständigkeit und Druckfestigkeit. Es ist die ideale Wahl für Lösungen, die Belastbarkeit und Präzision erfordern.

EPPE

Expandiertes Polyphenylether ist der ideale Partikelschaum für dünnwandige Formgebungen. Es erfüllt höchste Anforderungen an Flammschutz und Temperaturbeständigkeit.

Unsere Kompetenzen verschmelzen in marktführenden Partikelschaumlösungen

Seit über 140 Jahren entwickelt und produziert RUCH NOVAPLAST führende Partikelschaumlösungen. Über die Jahrzehnte haben wir unsere Material- und funktionale Produktkompetenz geschärft. Wir haben zudem eine Verfahrens- und Fertigungskompetenz entwickelt, mit der wir für Sie Unmögliches möglich machen. Das Zusammenspiel unserer vier Kompetenzbereiche ist einzigartig in Europa.

Vier Kompetenzbereiche. Ein Ziel. Einzigartig in Europa.

In mehr als 20.000 Projekten haben wir unsere Kompetenzen perfektioniert, um auch komplexe Anforderungen erfüllen zu können.

Technische Anwendungen aus expandierbaren Polymeren sind unser Spezialgebiet

Als Spezialist für Formteile und Gehäusesysteme aus expandierbaren Polymeren bieten wir individuelle Partikelschaumlösungen für technische Anwendungen in verschiedenen Branchen. Unsere Partikelschaum-Formteile zeichnen sich durch hohe Dichtigkeit, Durchschlagsfestigkeit, elektromagnetische Verträglichkeit und Temperaturstabilität aus.

Sie eignen sich ideal für anspruchsvolle Anwendungen in der Haus- und Gebäudetechnik, im Bereich Kopf- und Körperschutz, in der Medizin- und Analysetechnik sowie im Bereich Mobilität.

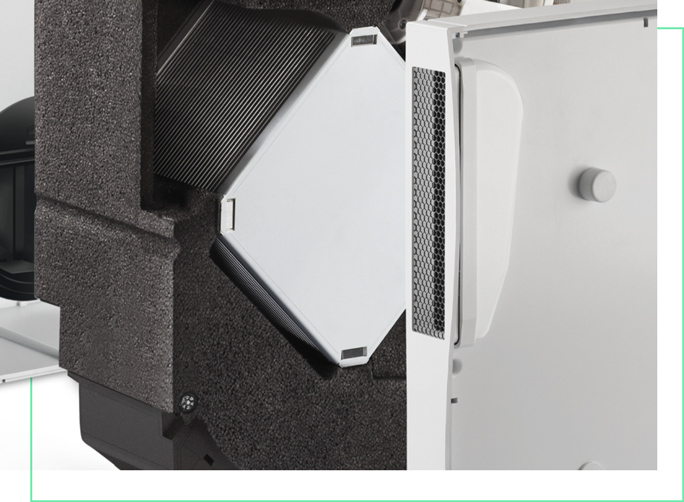

Haus- und Gebäudetechnik

In der Haus- und Gebäudetechnik überzeugen unsere innovativen Partikelschaumlösungen besonders durch ihre ausgezeichneten Dämm- und Isoliereigenschaften.

Medizin- und Analysetechnik

Unsere innovativen EPP-Formteile schützen in der Medizin- und Analysetechnik empfindliche Bauteile von hochspezialisierten Geräten vor Stoßbelastungen und zu starken Temperatureinflüssen.

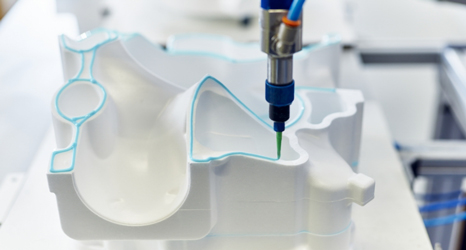

ideen form geben – mit unseren Innovationen

RUCH NOVAPLAST ist seit vielen Jahren Technologieführer im Bereich der Partikelschäume. Mit modernster Innovationskraft entwickeln wir effiziente und neuartige Fertigungsverfahren für die Herstellung hochwertiger Formteile und Gehäusesysteme.

Wir setzen Ideen zu kreativen Lösungen um.

Unsere Innovationen setzen neue Standards im Bereich Partikelschäumen.

RUCH NOVAPLAST formt die Zukunft mit hochfunktionalen Produkt- und Systemlösungen

Die Märkte verändern sich ständig – bei RUCH NOVAPLAST nehmen wir diese Herausforderungen mit Leidenschaft und Expertise an. Als Spezialist für Partikelschäume bieten wir hochfunktionale Produkt- und Systemlösungen, die genau auf Ihre Bedürfnisse abgestimmt sind.

Unser Team aus Ingenieuren, Technikern und Materialexperten entwickelt durch enge Zusammenarbeit richtungsweisende Innovationen. Wir setzen auf Teamgeist und kontinuierliche Weiterbildung, um stets die besten Ergebnisse zu erzielen – für Ihren Erfolg und eine nachhaltige Zukunft.

Aktuelle News und spannende Einblicke in unseren Alltag

Verschaffen Sie sich auf unserer News-Seite einen Überblick über unsere neuesten Fortschritte und Projekte. Erfahren Sie noch mehr Details über unsere innovativen Formteile und Gehäusesysteme.

Und bleiben Sie informiert über unsere Ansätze zur Bewältigung der Herausforderungen von morgen.

Werden Sie ein Teil von RUCH NOVAPLAST

Unsere Mitarbeitenden sind der Schlüssel zum Erfolg. Wir bieten ein Arbeitsumfeld, das von Fachwissen, Wertschätzung und Teamgeist geprägt ist. Egal ob als erfahrene Fachkraft, Azubi, Praktikantin oder Praktikant – bei RUCH NOVAPLAST erwarten Sie spannende Aufgaben und attraktive Benefits. Werden Sie Teil unseres Teams und formen Sie mit uns die Zukunft. Bewerben Sie sich jetzt!