EPA: the high-performance particle foam for extreme applications

Expanded polyamide (EPA) is a high-performance material with exceptional temperature resistance, impressive impact strength and compressive strength. It is ideal for long-term use in demanding mechanical and thermal environments that have to withstand temperatures of up to 150 °C (continuous operating temperature). This clearly sets this particle foam apart from other materials.

EPA is particularly in demand in the development of solutions for high-temperature applications. Thanks to its robust properties, expanded polyamide is the ideal choice for applications that require maximum resilience and precision.

Where high temperature resistance and lightweight construction are important: EPA

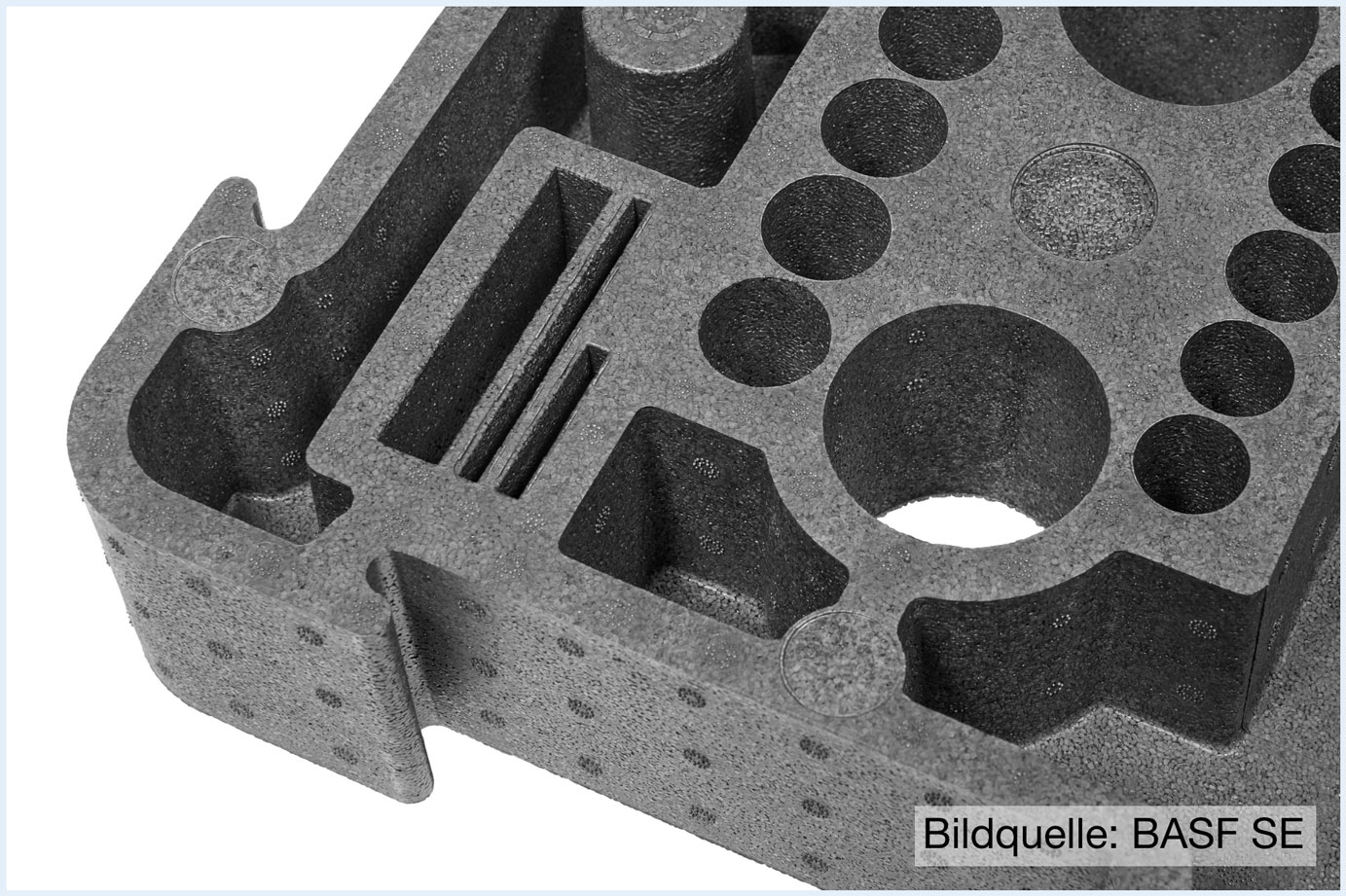

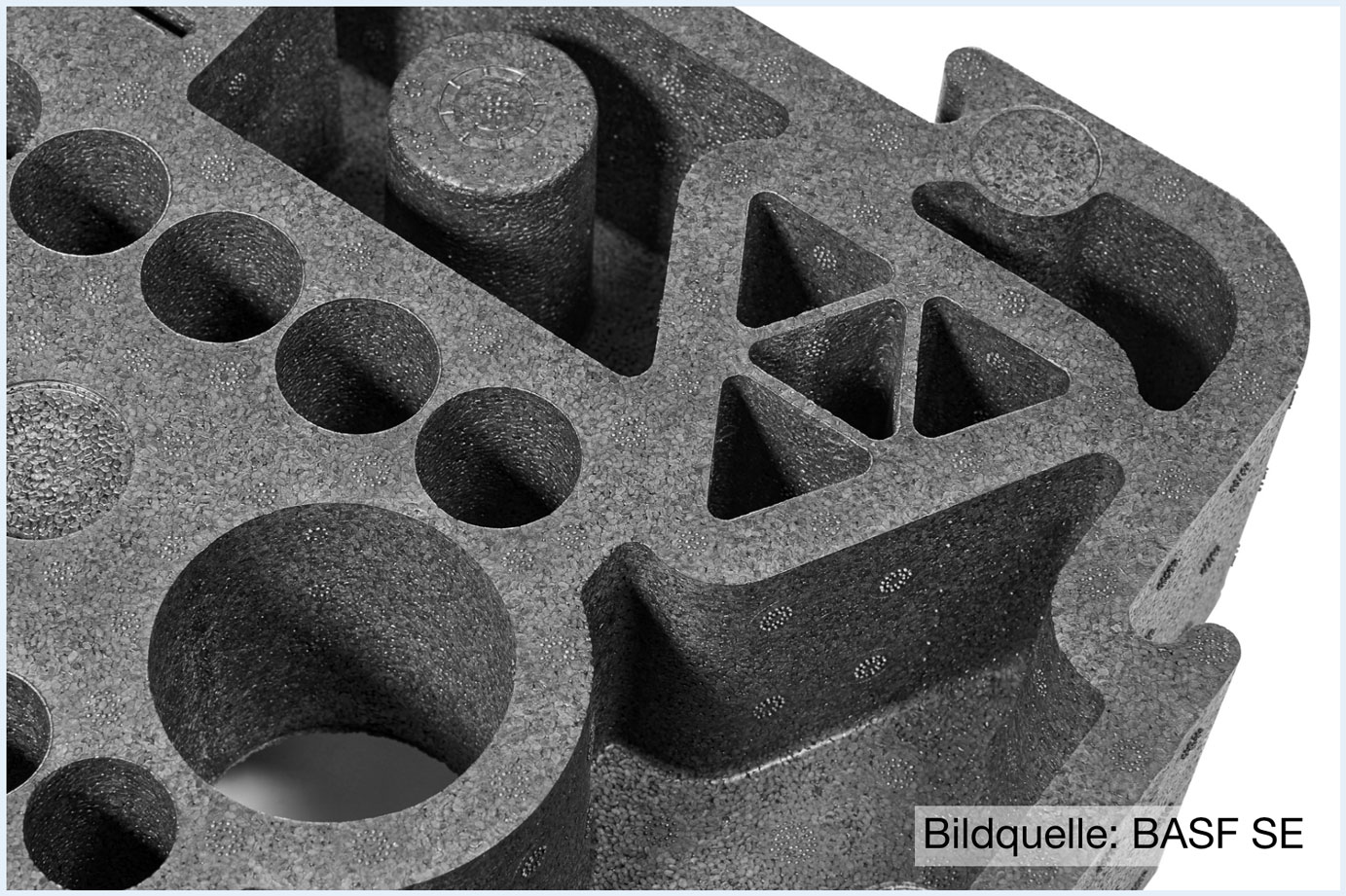

High-performance EPA particle foam molded parts impress when it comes to extreme temperature resistance and robustness. Possible applications are in the automotive sector or technical components subject to thermal stress. Here is a selection:

- Crash and energy absorber

- Thermally stressed components, such as battery housings or brackets, battery modules for e-mobility

- Structural components with thermal or mechanical stresses, such as impact absorbers

- Enclosure parts and components in demanding industrial environments

- Complex lightweight hybrid parts and components

Good properties in high-temperature environments:

the most important properties of EPA

Expanded polyamide and what characterizes the particle foam – here at a glance:

Flexible shaping

The EPA material makes filigree molded part geometries possible.

High temperature resistance

The material is extremely resistant to high temperatures.

Toughness

The material retains its shape even at low temperatures.

Pressure resistance

EPA molded parts are characterized by high rigidity and strength.

Excellent heat resistance

EPA retains its shape and properties even at higher temperatures.

Mechanical properties

Expanded polyamide is also ideal for use at high temperatures.

Good chemical resistance

EPA is resistant to oils, fuels and lubricants.

The material EPA

BASF supplies polyamides for various processing applications under the trade name Ultramid® Expand.

Depending on the requirements and/or field of application, various material types are available that are tailored to the specific requirements. They all impress with their high mechanical strength, accompanied by outstanding temperature resistance and dimensional stability, making them the ideal material for demanding technical applications.

In combination with other particle foams, exciting possibilities for hybrid solutions arise – wherever structural stability meets lightweight construction.

At RUCH NOVAPLAST, we use the advantages of these high-performance polyamides to create customized components that combine functionality, precision and durability.

EPA – another recyclable thermoplastic

EPA is a technically high-performance plastic that harmonizes functionality and sustainability. The production of EPA molded parts is energy-efficient and uses a minimum amount of material. Thanks to precise tool technology and optimized process parameters, we reduce waste and raw material consumption to a minimum. In addition, a proportion of recycled material can be incorporated into the production process as required without compromising the performance of the end product.

Resource-conserving circular economy

The material is fully recyclable and can be reprocessed into new particle foam at the end of a product’s life cycle – without any significant loss of mechanical or thermal properties. This means that the material is permanently retained in the material cycle – in line with a sustainable materials strategy.

Frequently asked questions about the EPO: briefly and concisely summarized

If you have any questions about the EPO, you may find the answers here. If not, please feel free to contact us personally at any time.

EPA stands for expanded polyamide. This is a high-performance particle foam that is produced by heating and foaming polyamide granulate and then processed in foaming tools. The result is lightweight, stable and highly temperature-resistant molded parts.

EPA is still a relatively new material. It is primarily known from the automotive industry – as a structural component in the engine compartment, in battery modules of electric vehicles or as an energy-absorbing element in crash zones.

EPP (expanded polypropylene) is characterized by good elasticity and shock absorption, is known from reusable packaging and transport boxes and can withstand temperatures up to +110 °C.

EPS (expanded polystyrene) is less expensive, but only has limited temperature and chemical resistance and is known for disposable packaging pads.

EPA (expanded polyamide) is mechanically even more robust, temperature-resistant up to +190 °C (short-term) and very dimensionally stable – ideal for high-performance applications with continuous application temperatures up to +150 °C.

Yes, like other thermoplastics, EPA can be shredded and reprocessed.

The material costs for EPA are higher compared to EPP or EPS. As a polyamide absorbs moisture – in contrast to EPP or EPS – careful storage is necessary. Processing is also somewhat more demanding due to narrower process windows.

EPA remains dimensionally stable and resilient even at temperatures of up to 190 °C (short-term operating temperature). This makes it significantly more heat-resistant than EPP or EPS.

Yes, polyamide is resistant to many oils, lubricants, fuels and chemicals found in the automotive and industrial sectors. This makes EPA particularly interesting for use in harsh environments.

Yes, the combination of high compressive strength, crash energy absorption and temperature resistance makes EPA an attractive material for safety-critical applications – for example in crash absorbers or battery housings.

Expanded polyamide is a thermoplastic material and therefore fundamentally recyclable. In addition, lightweight construction contributes to CO₂ savings during operation, e.g. in vehicles.