We are shaping the future with our innovations

RUCH NOVAPLAST is on the move – continuously, purposefully and always in search of something new. As a technology leader in the field of particle foams, we combine over 140 years of experience with state-of-the-art innovation to constantly push the boundaries of what is possible for you. Our expertise in the development of innovative molded parts and complex housing systems is based on a deep understanding of particle foams and your requirements as a customer.

With 21 of our own property rights and a dedicated innovation team of seven specialists, we set standards in particle foaming. Our 55 successfully implemented innovation projects show how creative solutions not only increase the efficiency and functionality of our particle foam components, but also deliver sustainable results – such as the saving of 54,000 tons of CO₂ through pioneering projects.

This is what moves us forward

As true particle foam pioneers, we are shaping the future: by continuously developing our materials, optimizing processes and working in partnership with our customers. For us, innovation means shaping ideas and creating something new.

We are shaping innovations from particle foams

As Europe’s technology leader in the field of particle foam, we set standards: with our innovations, we create pioneering solutions that combine functionality, efficiency and aesthetics. Our technologies revolutionize the areas of assembling components, insulating devices, fastening elements, joining moulded parts and finishing surfaces – and offer you crucial competitive advantages.

Each of these innovations is based on our many years of experience and our comprehensive expertise in design, energy efficiency, material development and process optimization. With these technologies, we turn ideas into production-ready solutions – for inspiring and shaping the future.

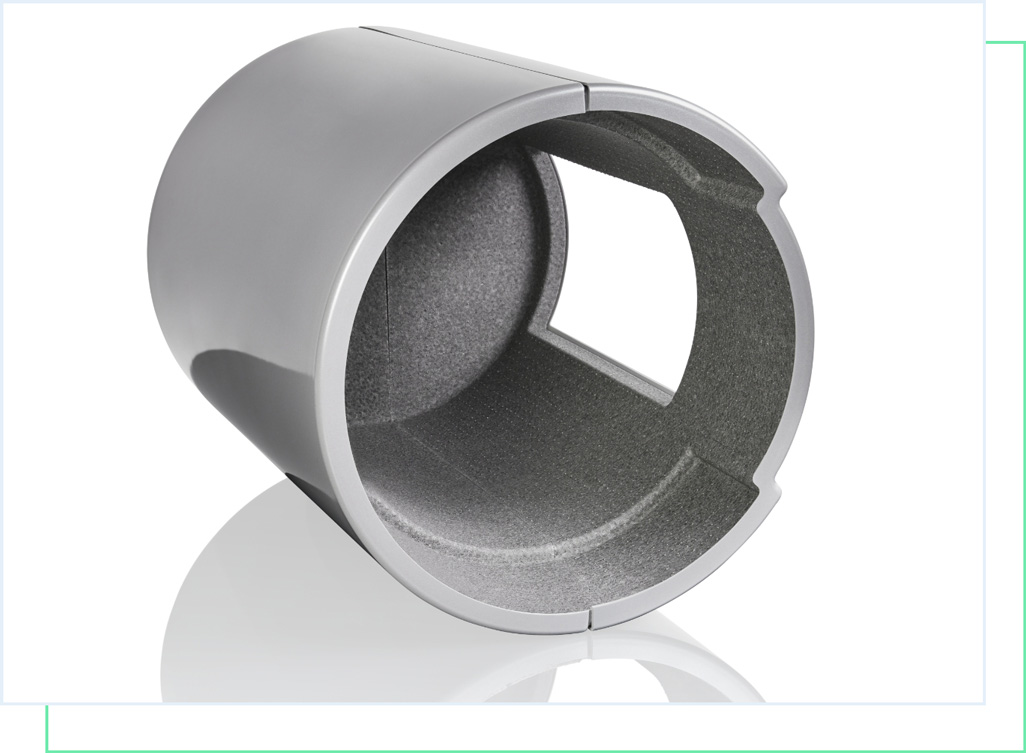

Assembling components

With NOVAplex®, we are setting new standards in assembly: components are quickly and easily inserted into molded parts – without any time-consuming screwing. Find out how our innovative design philosophy optimizes assembly processes.

Fastening elements

With NOVAfeed&fix® and NOVAson®, we offer innovative solutions for fastening elements. Discover how our technologies integrate precise and flexible fastening options into enclosure systems.

Finishing surfaces

With NOVAtexture®, we refine particle foam molded parts directly during production. Find out how our innovative technology creates beautifully shaped and functional surfaces that improve the look and feel.

We develop and qualify product and process innovations to create particle foam solutions that are ready for series production in established existing markets or to open up new markets. Our focus is on developing solutions that support the needs of our strategic market segments with innovative product features. Through the use of innovations and processes, we transform the rapidly changing variety of particle foams and combination solutions into customized product solutions for our customers.