Our functional product expertise stands for quality and reliability

Our molded parts made of particle foam create great benefits and added value for you – individually, as an assembly and also as a complex system chassis. With each project, we have further expanded our functional product expertise. Always with the aim of taking your products to the next level in terms of function, quality and cost-effectiveness.

At RUCH NOVAPLAST, you can rely on us to focus on your requirements at all times.

What sets our molded parts apart

The functions and properties of our molded parts are diverse. They range from thermal requirements and surface properties to acoustic or microbial properties. We often push the boundaries of what is feasible and create completely new applications for particle foams, for example complex, energy-saving system chassis.

Functions of our molded parts

Our molded parts offer a wide range of functional properties that are specifically tailored to the needs of your application. From integral hinges that enable flexible folding functions, to functionalization with inserts for integrated fastening elements, to innovative solutions for insulation and airflow that ensure optimum cooling. We also offer tailor-made solutions for sound and acoustic optimization to minimize disruptive noise. In addition, we guarantee maximum precision and quality in production through tolerance optimization.

Integral hinges enable practical folding functions and simplify assembly, especially in the case of lateral undercuts that would normally have to be realized with complex slides. Here, the use of integral hinges simplifies the tool design. By folding away the wall, the undercuts generally move in the demolding direction – the moulded part remains in one piece.

If there is no possibility of snapping the components together due to a lack of space and low wall thicknesses in a multi-part set of molded parts, we solve this problem with integral hinges.

Integral hinges are created by compressing and vaporizing the particle foam during the manufacturing process. This creates a plasticization in a thin area that is very durable and robust.

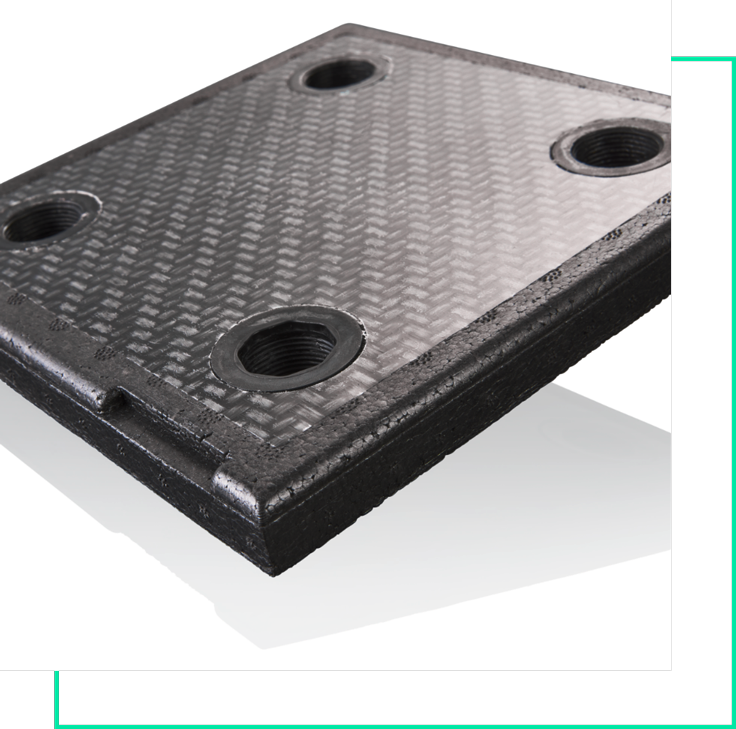

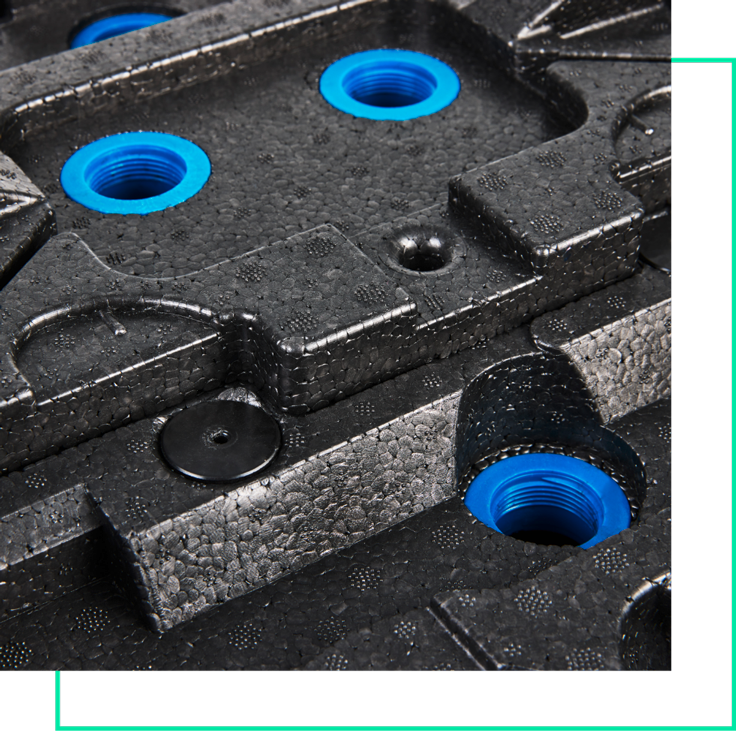

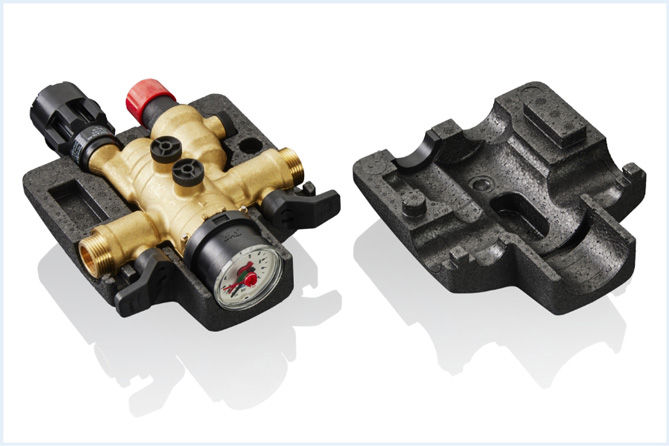

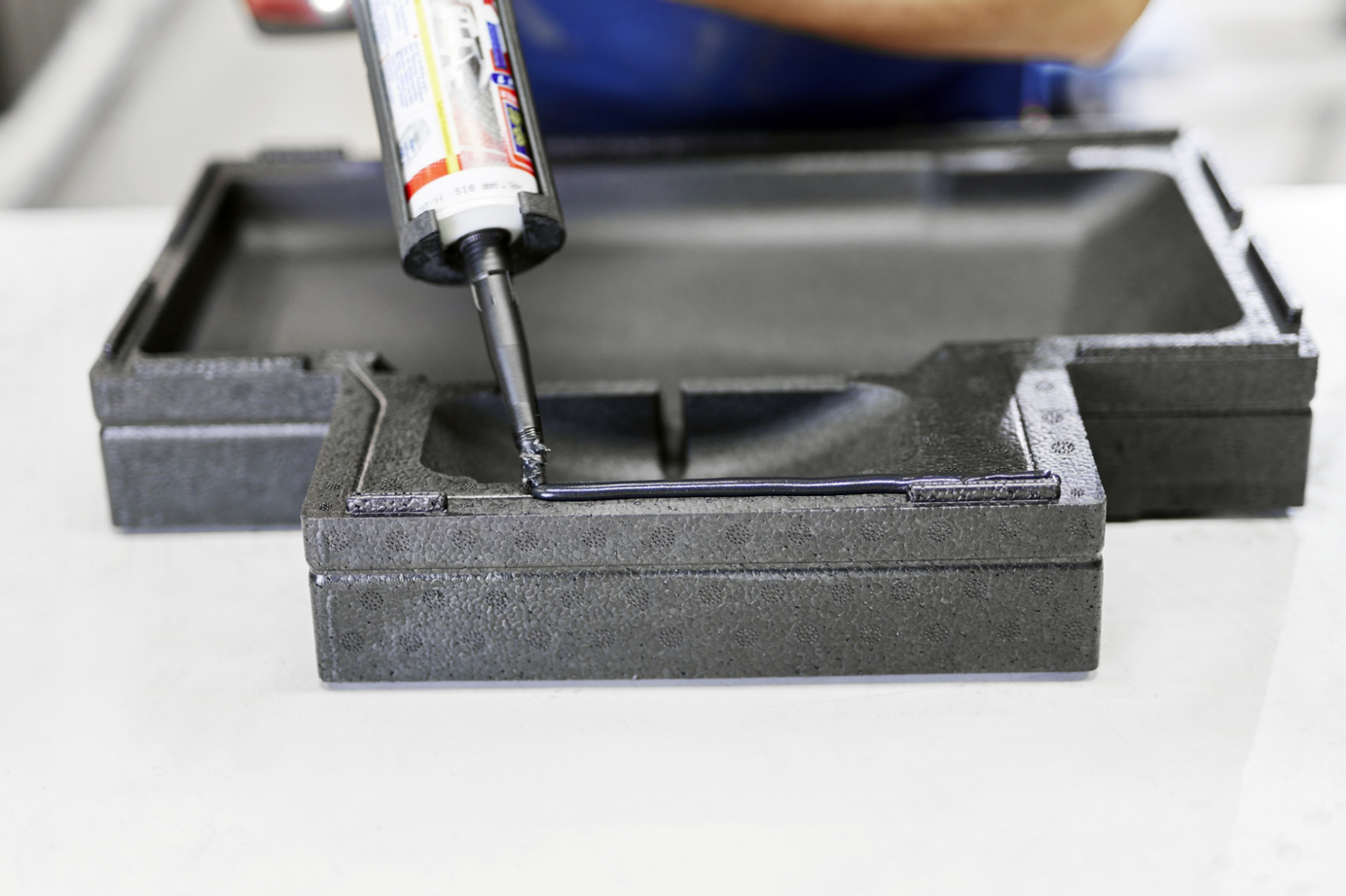

Particle foam is functionally enhanced by the integration of fastening elements. Inserts are increasingly in demand, particularly in the house and building technology. RUCH NOVAPLAST offers a flexible modular system of different fastening elements that can be used depending on the application. In this way, pressure-resistant and leak-proof cable ducts with strain relief and bend protection, hose couplings, sensor mountings and hinge attachment points for fixing other assemblies are possible – all integrated directly into the EPP chassis.

Depending on the available space, inserts made of many other materials and also with different contours can be foamed in. However, the process environment is limiting, especially the temperature and steam environment that the component has to withstand. The parts inserted manually or automatically in the mold are usually foam-fit to the component.

If only a simple and single attachment point is required or if the shape of the molded part allows no other option, a friction welding boss can be the fixing element of choice.

Particle foams not only offer excellent insulation values, but also ideal properties for targeted airflow management and heat dissipation. Thanks to the three-dimensional formability of molded parts, precise cooling channels can be designed that enable efficient heat dissipation directly at the source. This allows the flow velocity to be optimized to ensure reliable cooling and effectively protect your components from overheating.

For effective noise reduction in enclosures, we combine EPP with sound-absorbing materials to minimize the disruptive noises that occur with heat pumps. By decoupling compressors in an EPP chassis and using sound-absorbing hoods around outdoor units, the noise level can be significantly reduced. We offer you customized solutions for noise reduction and sound absorption that are optimally tailored to your requirements through comprehensive analyses and planning.

Tolerance optimization for foamed moulded parts is crucial to ensure consistently high quality. Even if the tolerances basically correspond to the ISO basic tolerances, various influencing factors such as raw material, density and the complexity of the component can affect the precision. RUCH NOVAPLAST has developed extensive know-how in the field of tool technology and process optimization in order to reduce or compensate for tolerances in a targeted manner. By using precise, shaping foaming tools, stable process monitoring and a deep understanding of material-specific properties such as shrinkage behavior, we ensure that your particle foam components are manufactured exactly according to the dimensional and functional requirements.

Properties of our molded parts

Our molded parts offer a wide range of functional properties that make them ideal for a wide variety of applications. They meet the highest requirements for fire protection, leak-tightness, dielectric strength and electromagnetic compatibility to ensure maximum safety and efficiency. They also offer microbial inertness and excellent temperature stability, even under extreme conditions.

The flammability and combustibility of building materials play a decisive role in fire protection. We support you in choosing the right material, accompany products through fire tests – either in-house or at our partner institutes – and ensure that all projects meet the strict fire protection requirements.

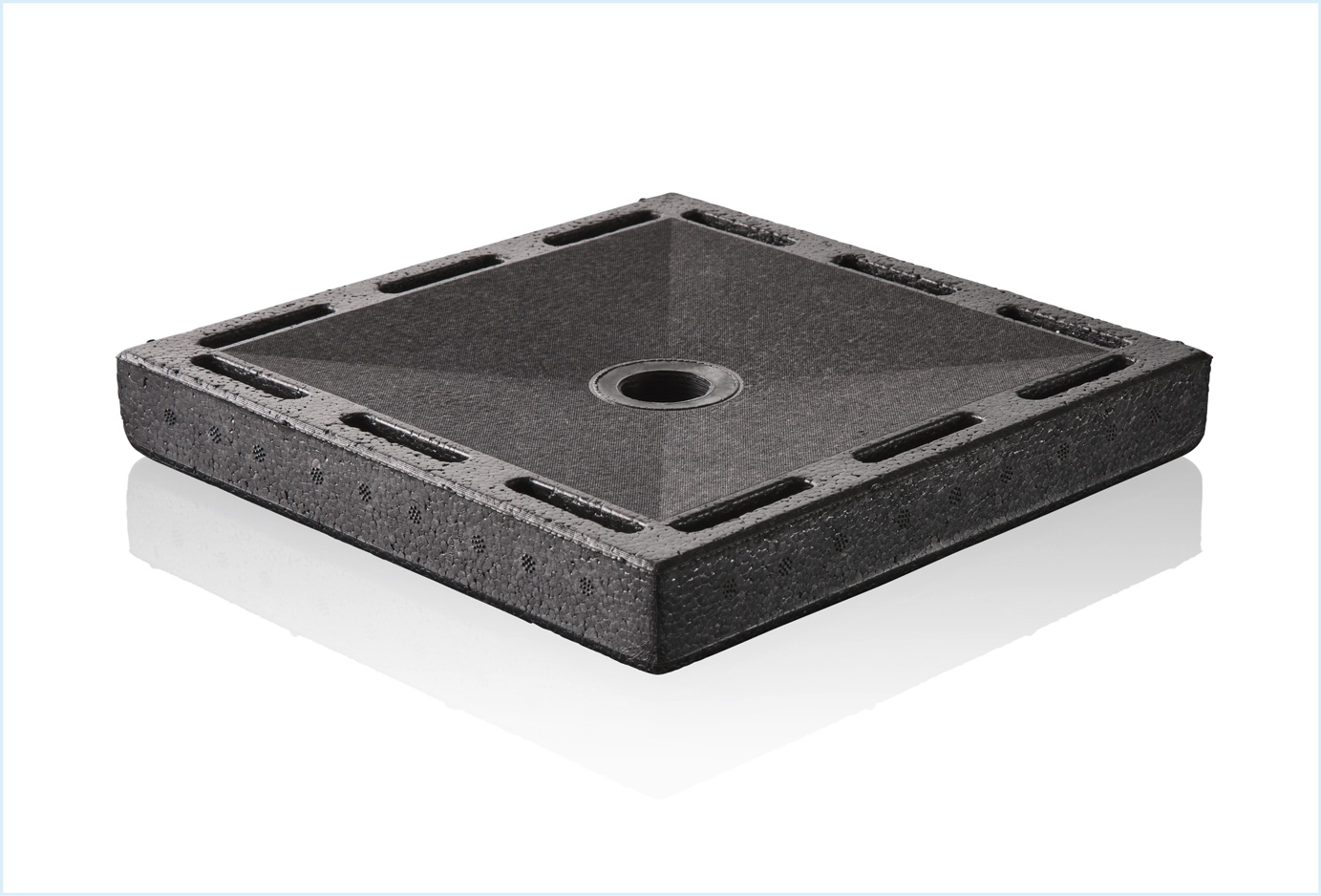

The leak-tightness of an overall construction depends crucially on the material properties and the quality of the structure. At RUCH NOVAPLAST, we achieve outstanding results through high fitting accuracy, innovative joining techniques and precise surface finishing. In many cases, our molded parts exceed the specified tightness values of the DiBt by more than 50 %. In relevant areas, for example, we guarantee 100% watertightness.

The housing solutions and system chassis from RUCH NOVAPLAST provide a functional structure for the components and conduct the currents to the inputs and outputs in accordance with defined key figures. The component itself also performs insulating and therefore energy-conserving or energy-saving functions. In air conditioning and ventilation systems, for example, it is important that ideally the same amount of air that flows into an air duct also flows out again at the end.

We set the bar particularly high for what is technically possible. We build complex housing solutions with leakage values that are far below the defined standard and focus on maximum energy conservation of the volume flow like no other.

Dielectric strength is crucial for the long-term safe operation of electrically and mechanically functioning products. Our molded parts made of polymer materials such as EPP not only meet high mechanical and electrical requirements, but also fire protection standards. The specific environmental conditions under which the end product is used also influence these requirements. With in-depth expertise and experience, we select the right materials and develop customized designs that offer high dielectric strength performance, ensuring the safety and longevity of your products.

Electromagnetic compatibility (EMC) is a key aspect in the development of modern devices. We support our customers in the design of assemblies and the layout of their products to ensure that electromagnetic interference is reliably minimized. With various options such as special coatings or films that create an EMC-active surface on our molded parts, we ensure an optimal design for your applications so that your devices work safely and without interference.

The particle foams that we process meet the strict requirements of VDI 6022 (Sheet 1) for microbial inertness. This means that they do not promote the growth of fungi or bacteria. The renowned Institute for Air Hygiene (ILH) has confirmed this property. The special NOVAtexture® surface finish and the avoidance of pore formation in the surface further optimize microbial inertness, while at the same time achieving excellent condensate impermeability of the particle foam.

Our particle foam solutions offer outstanding temperature stability with a continuous temperature resistance of -50 to +200 °C. Each material is specially adapted to its area of application in order to function reliably even at extreme temperatures. We take into account factors such as mechanical power loss, creep and degradation to select the right particle foam material for each application, delivering consistently high performance under all conditions.

Particle foams are our passion. We know exactly what we can demand of them – whether delicate or enhanced with a variety of properties and benefits. We work with our customers to find the right product solution based on their specific requirements.