Our solutions for house and building technology

We are setting new standards in hous and building technology with our innovative molded parts and complex housing systems made of particle foam. As a technology leader, we develop individual solutions that are not only energy-efficient, but also sustainable and resource-saving.

Our products, such as heat pump chassis and reveal elements made of EPP, play a decisive role in this industry.

Applications in building technology

Efficient and environmentally friendly solutions are essential in modern building technology. Thanks to our NOVAplex® technology, we offer you innovative products that revolutionize the manufacture of heat pumps, ventilation units and air purifiers. Our EPP housing systems provide significant advantages in terms of cost, installation and integration – especially for heating, ventilation and air conditioning (HVAC).

Heat pumps and ventilation systems with heat recovery are now standard in new buildings in order to improve air quality and optimize energy consumption at the same time. With NOVAplex®, RUCH NOVAPLAST has developed a solution that not only simplifies the manufacture of these systems, but also promotes their efficiency and sustainability.

Heat pumps are a particularly environmentally friendly and efficient heating technology that is increasingly being used in the modernization of existing buildings. The most commonly used technology is the air/water heat pump. It uses the heat stored in the air to provide heating and hot water and can also cool in summer. The heat pump can be installed either inside or outside the building.

The air/water heat pump installed indoors draws in air from the environment via a grille in the façade. It therefore uses the same energy source as a heat pump for outdoor installation. This requires air ducts to guide the outside air to the heat pump and back outside again. Our air ducts made of EPP are characterized by high thermal insulation with minimum weight and reliable tightness. We can even create 90-degree bends without flow resistance and with minimal space requirements. The advantage is that the technical devices are located inside the building and can be coupled directly with a ventilation unit. The result is a modular energy supply concept whose chassis is itself a highly functionalized system. The multi-part EPP chassis accommodates all components in a form-fitting manner and holds them in place. Behind this is the successful NOVAplex® design concept.

For externally installed heat pumps, we bring together all the important technical components of the heat recovery process in the outdoor unit. Inside the housing, molded parts made of expanded polypropylene (EPP) ensure that the individual components are held securely in place. Depending on the scope of integration, it is a particular challenge to manufacture all the individual parts in such a way that they are perfectly matched to each other and there is no misalignment. The mold part tolerances are kept correspondingly tight. In addition, external heat pumps and air conditioning units often cause a noise level. A sound insulation hood made of EPP can help here. In addition to sound insulation, it also offers protection against vandalism and the effects of the weather. It is also possible to install external heat pumps directly on the house façade. Mounting elements for the façade from RUCH NOVAPLAST are useful for this.

Ventilation units with heat recovery ensure a constant supply of fresh air by extracting stale indoor air and drawing in fresh outdoor air at the same time. By transferring the heat from the exhaust air to the supply air, heating energy is used efficiently and heating costs are reduced. Depending on the structural conditions, these devices can be installed both centrally and decentrally.

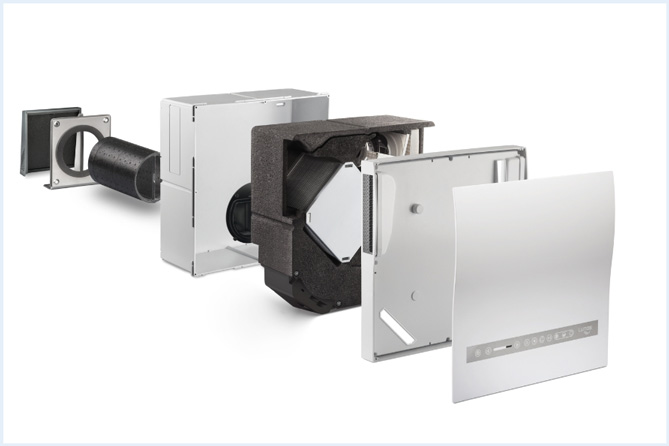

Central ventilation units are complex systems. They consist of a ventilation unit with fans and heat exchanger as well as the associated air distribution system. Inside, housing solutions from RUCH NOVAPLAST provide clarity and structure. A housing typically consists of multiple EPP molded parts, which we join together into a chassis using thermal joining. This material joining results in excellent insulation, significantly reducing condensation and ensuring airtightness. The result is increased overall system efficiency. In addition, the EPP chassis enables optimal air flow management through the design of ventilation ducts. We install the individual components of the ventilation unit by simply plugging them into the specially designed recesses in the EPP housing, thus holding them securely in place. Behind this is our innovative NOVAplex® design concept.

We generally use laser-textured molded parts in the condensate drip tray area. The result is a watertight surface that can safely drain condensate. We insert NOVAfeed&fix® elements into the foam in a firmly bonded manner to drain off the funnel-shaped condensate. The same surface finishing process can also be used on the outside of the chassis, but for visual reasons.

With decentralized ventilation units, an individual room is ventilated without the use of a central air distribution system. The units are installed directly in the external walls. The lower installation costs make the decentralized ventilation system very attractive for renovations of old and existing buildings. The interior of the ventilation units consists of several molded parts made of EPP. Some of them are permanently joined together using a thermal joining process – without any additional material. This allows us to join even thin walls in an airtight manner. Decentralized ventilation units can be flexibly integrated into the building architecture: Whether a partially recessed installation in the wall, assembly beneath the ceiling or along a jamb wall in the attic, the complex EPP solutions from RUCH NOVAPLAST adapt to various requirements.

Good indoor air quality is crucial for our health and well-being. Especially in rooms with limited ventilation options, measures are necessary to improve the air quality. Air purifiers are an excellent solution for this. They filter pollutants and allergens out of the air and thus promote indoor hygiene.

Efficient air purifiers rely on the harmonious interaction of numerous components that work together perfectly in a robust housing made of expanded polypropylene (EPP). There they are held securely and firmly in the EPP molded parts. Behind this is our NOVAplex® design concept. The basic idea is child’s play: insert components instead of screwing them together. This means that all components are positively embedded in the EPP chassis – without additional screws, clamps or metal sheets. In addition to saving costs in the procurement of C-parts, this innovation from RUCH NOVAPLAST also reduces assembly time.

Effective room air purification also requires a strong air flow. Our EPP chassis can be designed in such a way that it takes over the airflow itself and thus optimally guides the airflow through the housing.

Low density, high insulation capacity and flexible adaptation – hardly any other material combines these properties as well as expanded polypropylene (EPP). It is therefore hardly surprising that EPP has established itself as the material of choice for insulation parts, particularly in heating technology. We integrate components such as pumps, fittings and simular elements directly into our EPP chassis. As a result, we not only fix assemblies in place, we also reduce the number of purchased parts such as additional fastening elements. The EPP housing solutions from RUCH NOVAPLAST ensure lightweight and precise assembly.

Applications in building technology

In modern building technology, our façade and installation elements made of mostly high-density particle foams are crucial. This is because we offer you elements that enable thermal bridge-free and force-fit installation. They can be installed precisely and securely as add-on parts without affecting the insulation material.

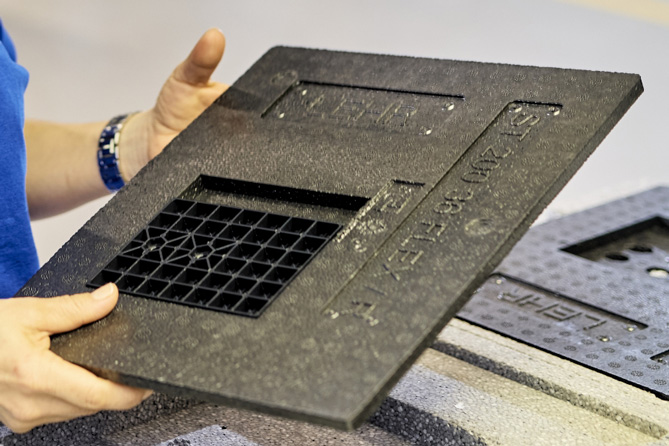

Reveal elements form the façade closure of decentralized ventilation units and ensure precise installation, optimized air exchange and reliable thermal insulation – a plus for every season. Thanks to flexible flat ducts made of EPP, a wide variety of installation situations can be realized and the positioning of the core drill hole in the outer wall can be individually adapted.

The reveal elements consist of precisely matched molded parts that we can securely join together using thermal joining. Complete by accessories such as ventilation grilles, plugs and installation instructions, RUCH NOVAPLAST supplies the elements ready for installation upon request – for easy integration and maximum efficiency.

When attaching fastening elements to the exterior wall of a building, the insulation must not be compromised, as even small thermal bridges promote condensation or mold growth. Assembly elements made of high-density expanded polystyrene (EPS) offer an ideal solution for secure, thermal bridge-free installation of façade elements such as roller shutter systems or external wall sockets.

Pre-wall installation systems enable windows to be installed safely and easily in the insulation level of the façade – an indispensable solution for energy-efficient renovations with external thermal insulation composite systems. The systems made of high-density expanded polystyrene (EPS) impress with their excellent load-bearing capacity for securely supporting the weight of the window and can still be flexibly adapted to individual requirements.

Thanks to their excellent thermal conductivity class, the moulded parts fit seamlessly into the insulation concept, optimize thermal bridges and ensure first-class insulation in the reveal area. This effectively minimizes the risk of mould forming in the connection area around the window opening.

Efficient energy supply and optimum indoor air quality

Modern new buildings and energy-efficient renovations rely on an efficient energy supply and airtight building envelopes to minimize heat loss. Ventilation units and air distribution systems ensure constant air exchange and healthy indoor air quality, while natural heat sources such as air, soil or groundwater are used via heat pumps.

Our EPP housing systems play a crucial role here. Thermal and cold insulating molded parts made of particle foam provide reliable sealing and optimum airflow within the device. The material compensates for component tolerances, simplifies assembly and ensure airtightness and condensate resistance – key requirements for maximum efficiency and quality. This results in innovative solutions for climate-friendly living.

The requirements for energy-efficient systems are high and will continue to increase. Ventilation units and heat pumps designed on the basis of EPP housing systems already score points in the design of the units and already meet these high requirements today.